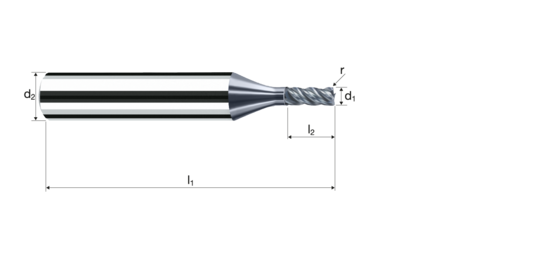

Corner radius end mills

Product ID: P15226180

Smooth-edged, normal version, POLYCHROM

Discontinued

Ø Code | d1 e8 | d2 h6 | l1 | l2 | l4 | r 0/+0.03 | α° | z |

|---|---|---|---|---|---|---|---|---|

| 180 | 3 | 6 | 57 | 8 | 15.56 | 0.5 | 6 | 4 |

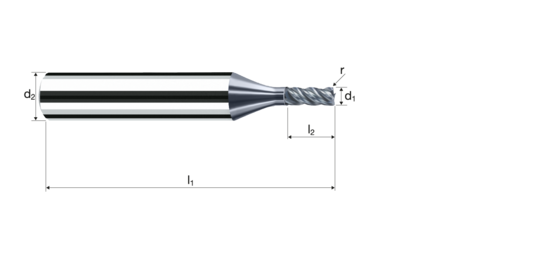

Smooth-edged, normal version, POLYCHROM

Ø Code | d1 e8 | d2 h6 | l1 | l2 | l4 | r 0/+0.03 | α° | z |

|---|---|---|---|---|---|---|---|---|

| 180 | 3 | 6 | 57 | 8 | 15.56 | 0.5 | 6 | 4 |