Cylindrical/Square end mills HX

Product ID: H8514300

Smooth-edged, medium version, short neck, High-performance penetration edge, DURO-Si

- Finishing

- Roughing HDC

- Roughing HPC

DURO-Si

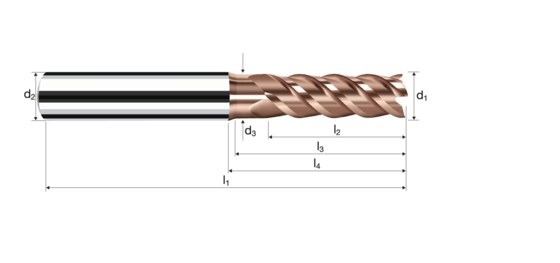

Ø Code | d1 e8 | d2 h6 | d3 | l1 | l2 | l3 | l4 | r | α° | z |

|---|---|---|---|---|---|---|---|---|---|---|

| 300 | 6 | 6 | 5.5 | 63 | 21 | 25.34 | 26 | 0.15 | 0 | 4 |