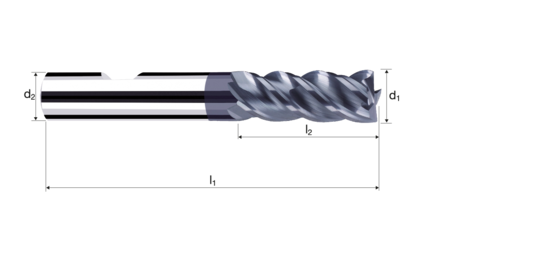

Cylindrical/Square end mills NVD

Product ID: P15307610

Smooth-edged, normal version, POLYCHROM

- Finishing

- Roughing HDC

- Roughing HPC

POLYCHROM

Ø Code | d1 e8 | d2 h6 | l1 | l2 | 45° | α° | z |

|---|---|---|---|---|---|---|---|

| 610 | 16 | 16 | 92 | 32 | 0.15 | 0 | 4 |

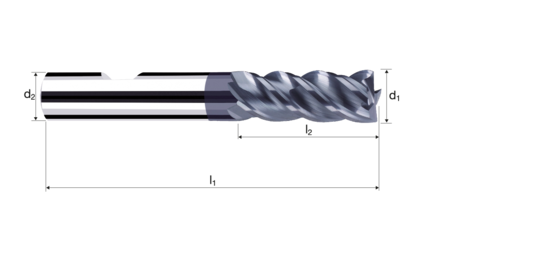

Smooth-edged, normal version, POLYCHROM

Ø Code | d1 e8 | d2 h6 | l1 | l2 | 45° | α° | z |

|---|---|---|---|---|---|---|---|

| 610 | 16 | 16 | 92 | 32 | 0.15 | 0 | 4 |