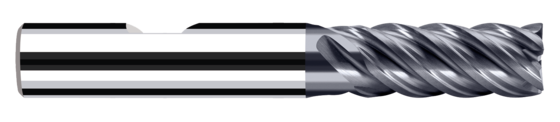

Cylindrical/Square end mills E-Cut

Product ID: P8405682

Smooth-edged, normal version, short neck, POLYCHROM

- Finishing

- Roughing HDC

- Roughing HPC

POLYCHROM

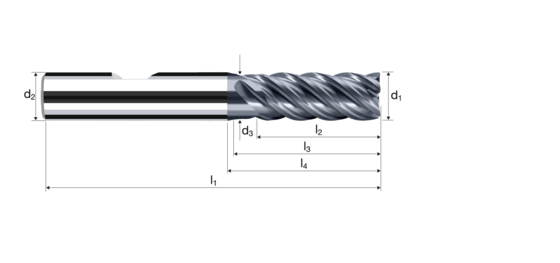

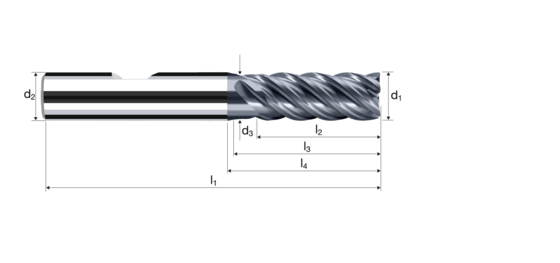

Ø Code | d1 e8 | d2 h6 | d3 | l1 | l2 | l3 | l4 | r | α° | z |

|---|---|---|---|---|---|---|---|---|---|---|

| 682 | 20 | 20 | 19 | 104 | 40 | 48.23 | 53 | 0.25 | 0 | 5 |

Smooth-edged, normal version, short neck, POLYCHROM

Ø Code | d1 e8 | d2 h6 | d3 | l1 | l2 | l3 | l4 | r | α° | z |

|---|---|---|---|---|---|---|---|---|---|---|

| 682 | 20 | 20 | 19 | 104 | 40 | 48.23 | 53 | 0.25 | 0 | 5 |